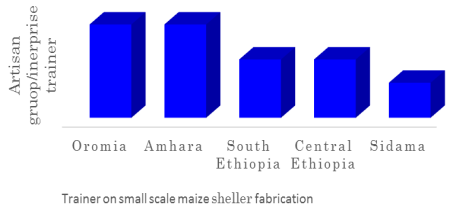

The current Ethiopian policy is to strengthen mechanization to improve crop production. The economy depends on agriculture, and the technology imported challenges Ethiopian inducers. The best option is the strength of local manufacturers and artisans. The purpose of this training was to strengthen the artisan and youth groups to improve fabrication quality. The training was conducted on fabrications of maize sheller and metal silo at Melkassa Agricultural Research Centre. The parts of Sheller are: supporter, drum, engine, shaft, chain, and sprocket. The sheller parameters are: speeds, moisture, shelling capacity, efficiency, and grain damage. Metal silo designs parameters: diameter of silo, height, thickness, and density of crop. The material used was galvanized sheet metal (28 gauge), lead, acid, and benzene. The trainers come from Oromia, Amhara, Central Ethiopia, Sidama, and the South Ethiopia region. They equally participated in maize sheller and metal silo fabrication. Oromia and Amhara (28%), Central and South Ethiopia (17%), and Sidama (10%) of the artisans successfully participated. They cover theoretical and practical sessions, and they can fabricate quality sheller and metal silos. After the training, they can develop their business, and it results in the minimizing of crop as it improves the accessibility of the technologies. Ethiopia's policy aims to improve crop production through mechanization, focusing on local manufacturers and artisans. A training program was conducted at the Melkassa Agricultural Research Centre to improve fabrication quality of maize shellers and metal silos. The training involved trainers from various regions, with 28% of participants successfully participating. The training helped artisans improve their skills, leading to business development and reduced crop loss, thereby enhancing technology accessibility.

| Published in | Science Development (Volume 6, Issue 3) |

| DOI | 10.11648/j.scidev.20250603.12 |

| Page(s) | 51-59 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Training, Maize Sheller, Metal Silo, Fabrication

No. | Region | Woreas | Metal silo Manufactured in 2023/2024 | Capacity of storage in (kg) | Cost of selling In (ETB) per unit |

|---|---|---|---|---|---|

1 | Oromia | Adami Tulu | 42 | 600 | 13500.00 |

2 | Oromia | Diremu | 138 | 69 was 300 69 was 600 | 7500.00 12500.00 |

3 | Oromia | Fedis book | 261 | 600 | 13500.00 |

4 | Oromia | Asasa | 65 | 600 | 1300.00 |

4 | Sidama | LakeAbbay | 25 | 600 | 13000.00 |

5 | Central Ethiopia | Dereshe | 265 | 14 was 300 251 was 600 | 7500.00 12500.00 |

6 | Central Ethiopia | Gordula | 50 | 50 was 600 | 12500.00 |

7 | Amhara | Debra Eliyas | 120 | 600 | 12800.00 |

EIAR | Ethiopian Institution of Agricultural Research |

FAO | Food and Agriculture Organization |

MARC | Melkassa Agricultural Research Center |

RHS | Rectangular Hollow Sections |

| [1] | M. Tadesse, “Post-Harvest Loss of Stored Grain, Its Causes and Reduction Strategies,” Food Sci. Qual. Manag., vol. 96, pp. 26–35, 2020, |

| [2] | H. H. Sarma, “Innovative Strategies for Minimizing Post-Harvest Loss in Agriculture,” vol. 4, no. July, 2024. |

| [3] | D. Amare, “Evaluation and Demonstration of Maize Shellers for Small-Scale Farmers,” MOJ Appl. Bionics Biomech., vol. 1, no. 3, 2017, |

| [4] | D. Yohannes, K. P. Kolhe, M. Dananto, and M. Mathewos, “Evaluation of Current Farm Machinery Utilization and Farm Productivity in Hadiya Zone, Central Ethiopia,” Res. World Agric. Econ., vol. 5, no. 4, pp. 203–216, 2024, |

| [5] | D. Darr, “Scaling strategies and mechanisms in small and medium enterprises in the agri-food sector : a systematic literature review,” no. May, pp. 1–16, 2023, |

| [6] | S. Debebe, “Post ‑ harvest losses of crops and its determinants in Ethiopia : tobit model analysis,” Agric. Food Secur., no. 2022, pp. 1–8, 2025, |

| [7] | S. G. Gebeyehu, “Developing appropriate business model for maize shelling technologies in small holder farmers in North West Ethiopian Districts,” Cogent Eng., vol. 10, no. 1, 2023, |

| [8] | B. G. Awoke and L. Kebede, Post-harvest Pest Management Research, Education and Extension in Ethiopia : The Status and Prospects Proceedings of the 22 nd Annual Conference Edited by Belay Habtegebriel (PhD) Plant Protection Society of Ethiopia, no. March. 2016. |

| [9] | P. Management and S. Of, “THE FEDERAL DEMOCRATIC REPUBLIC OF ETHIOPIA MINISTRY OF AGRICULTURE”. |

| [10] | A. Nebo and A. Tsegaye, “Pre-extension Demonstration of OARI-Assela Model-3 Multi Crop Thresher for Wheat and Sorghum in Arsi ZONE,” vol. 4, no. March, pp. 23–29, 2021. |

| [11] | J. Bwambale, O. S. Durodola, and V. Nabunya, “Development and evaluation of an improved maize silo to advance food security in Uganda Development and evaluation of an improved maize silo to advance food security in Uganda,” 2020, |

| [12] | G. Dyck, A. Rogers, and J. Paliwal, “A Review of Analytical Methods for Calculating Static Pressures in Bulk Solids Storage Structures,” KONA Powder Part. J., vol. 41, no. 41, pp. 108–122, 2024, |

| [13] | Y. Deribe, B. Getnet, T. G. Kang, and A. Tesfaye, “Benchmarking the Status of Agricultural Mechanization in Ethiopia Benchmarking the Status of Agricultural Mechanization in Ethiopia Research Report No. 133,” 2021. |

| [14] | GIZ, “Agricultural Mechanisation for Smallholder Farmers in Ethiopia,” 2024, [Online]. Available: www.giz.de/en/worldwide/65047.html |

| [15] | C. Liu and X. Liu, “Employee Training System of Manufacturing Enterprises for Implementing Industry 4.0,” J. Phys. Conf. Ser., vol. 1648, no. 4, pp. 0–8, 2020, |

APA Style

Aseffa, T., Kebede, L. (2025). Minimization of Postharvest Loss on Cereal Crops Through Capacity Building of Artisans and Youth Groups. Science Development, 6(3), 51-59. https://doi.org/10.11648/j.scidev.20250603.12

ACS Style

Aseffa, T.; Kebede, L. Minimization of Postharvest Loss on Cereal Crops Through Capacity Building of Artisans and Youth Groups. Sci. Dev. 2025, 6(3), 51-59. doi: 10.11648/j.scidev.20250603.12

@article{10.11648/j.scidev.20250603.12,

author = {Tasfaye Aseffa and Laike Kebede},

title = {Minimization of Postharvest Loss on Cereal Crops Through Capacity Building of Artisans and Youth Groups

},

journal = {Science Development},

volume = {6},

number = {3},

pages = {51-59},

doi = {10.11648/j.scidev.20250603.12},

url = {https://doi.org/10.11648/j.scidev.20250603.12},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.scidev.20250603.12},

abstract = {The current Ethiopian policy is to strengthen mechanization to improve crop production. The economy depends on agriculture, and the technology imported challenges Ethiopian inducers. The best option is the strength of local manufacturers and artisans. The purpose of this training was to strengthen the artisan and youth groups to improve fabrication quality. The training was conducted on fabrications of maize sheller and metal silo at Melkassa Agricultural Research Centre. The parts of Sheller are: supporter, drum, engine, shaft, chain, and sprocket. The sheller parameters are: speeds, moisture, shelling capacity, efficiency, and grain damage. Metal silo designs parameters: diameter of silo, height, thickness, and density of crop. The material used was galvanized sheet metal (28 gauge), lead, acid, and benzene. The trainers come from Oromia, Amhara, Central Ethiopia, Sidama, and the South Ethiopia region. They equally participated in maize sheller and metal silo fabrication. Oromia and Amhara (28%), Central and South Ethiopia (17%), and Sidama (10%) of the artisans successfully participated. They cover theoretical and practical sessions, and they can fabricate quality sheller and metal silos. After the training, they can develop their business, and it results in the minimizing of crop as it improves the accessibility of the technologies. Ethiopia's policy aims to improve crop production through mechanization, focusing on local manufacturers and artisans. A training program was conducted at the Melkassa Agricultural Research Centre to improve fabrication quality of maize shellers and metal silos. The training involved trainers from various regions, with 28% of participants successfully participating. The training helped artisans improve their skills, leading to business development and reduced crop loss, thereby enhancing technology accessibility.},

year = {2025}

}

TY - JOUR T1 - Minimization of Postharvest Loss on Cereal Crops Through Capacity Building of Artisans and Youth Groups AU - Tasfaye Aseffa AU - Laike Kebede Y1 - 2025/07/15 PY - 2025 N1 - https://doi.org/10.11648/j.scidev.20250603.12 DO - 10.11648/j.scidev.20250603.12 T2 - Science Development JF - Science Development JO - Science Development SP - 51 EP - 59 PB - Science Publishing Group SN - 2994-7154 UR - https://doi.org/10.11648/j.scidev.20250603.12 AB - The current Ethiopian policy is to strengthen mechanization to improve crop production. The economy depends on agriculture, and the technology imported challenges Ethiopian inducers. The best option is the strength of local manufacturers and artisans. The purpose of this training was to strengthen the artisan and youth groups to improve fabrication quality. The training was conducted on fabrications of maize sheller and metal silo at Melkassa Agricultural Research Centre. The parts of Sheller are: supporter, drum, engine, shaft, chain, and sprocket. The sheller parameters are: speeds, moisture, shelling capacity, efficiency, and grain damage. Metal silo designs parameters: diameter of silo, height, thickness, and density of crop. The material used was galvanized sheet metal (28 gauge), lead, acid, and benzene. The trainers come from Oromia, Amhara, Central Ethiopia, Sidama, and the South Ethiopia region. They equally participated in maize sheller and metal silo fabrication. Oromia and Amhara (28%), Central and South Ethiopia (17%), and Sidama (10%) of the artisans successfully participated. They cover theoretical and practical sessions, and they can fabricate quality sheller and metal silos. After the training, they can develop their business, and it results in the minimizing of crop as it improves the accessibility of the technologies. Ethiopia's policy aims to improve crop production through mechanization, focusing on local manufacturers and artisans. A training program was conducted at the Melkassa Agricultural Research Centre to improve fabrication quality of maize shellers and metal silos. The training involved trainers from various regions, with 28% of participants successfully participating. The training helped artisans improve their skills, leading to business development and reduced crop loss, thereby enhancing technology accessibility. VL - 6 IS - 3 ER -